Add to Cart

Porous ceramics,Ceramic chuck,Porous ceramic chuck table,Porous Ceramic Partial Vacuum Chuck

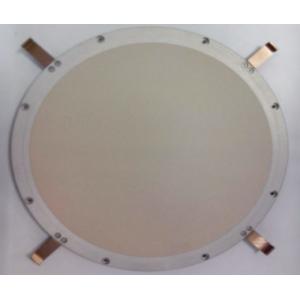

Porous Ceramic chuck table

Adhesive surface with planarity of 5μm max.

Brief inroduction

Work pieces can be adhesively fixed by aligning the porous to the body of the metal(or ceramic),and applying negative pressure from the back and sides of the body.

Due to the pores that are very tiny and averagely spread,vaccum chuck would not cause harms and scratch on your work pieces,improving the yield rate,making the best partner of manufacture.

Features

A. Reusable

B. Depletion resistance

C. No dust

D. Light weight

1. Shape Conformance to all shapes is possible

2. Size Round(Φ5mm~Φ600mm)Square(50mm*50mm~1000mm*1000mm)

Application

Semiconductors wafer dicing,grinding,washing,LEDs,printing

Precise Porous Ceramic Partial Vacuum Chuck

Best solution to the specific shape of work pieces

Features

A. Reginal adhesion

B. High heat resistance

C. Corrosion resistance

D. Depletion resistance

E. Lightweight

F. High insulation

G. No dust

Customize:specific size,shape,body material,porous size.

A. Modular design,can be installed in any institution or robot.

B. Porous base design for easy mounting.

C. Double vent design can be used for suction/blowing,floating.

D. Flatness:0.01~0.05mm

E. Customizable appearance size.

Applications

A. Ceramic Vacuum gripping module,special for gripping flat work piece.

B. If gripping half of the area can be maintained,then the ceramic gripper won't lose the work piece.Several work pieces can use same ceramic gripper.

C. Best for clean environment of machine production or factory production,assemble and automation industry.

Specification

| POROUS ALUMINA CERAMICS(Al₂O₃)Main Parameter:(Chemical/physical) | ||||

| Property | Item | Unit | ALUMINA | |

| General properties | Main chemical ingredient | Al₂O₃ 99.9% | ||

| Bulk Density | g/cm³ | 3.9 | ||

| Color | - | Ivory | ||

| Water absorption | % | 0 | ||

| Main Characteristics | *Good Anti-Plasma*Wear Resistance*High Purity | |||

| Main Applications | *Wear Resistant Parts*Chemically Resistant Parts*Semiconductor Processing Equipment Parts | |||

| Mechanical Properties | Flexural Strength | Mpa | 400 | |

| Elastic Modulus | Gpa | 380 | ||

| Vickers Hardness | Gpa | 17.5 | ||

| Compressive Strength 20℃ | Mpa | - | ||

| Fracture Toughness(k l c) | Mpa*M*1/2 | 5~6 | ||

| Thermal Properties | Thermal conductivity(20℃) | w/mk | 34 | |

| Thermal Shock | ℃ | - | ||

| Coefficient of Thermal expansion (40-400℃) | 1x10-6/℃ | 7.2 | ||

| Coefficient of Thermal expansion (40-800℃) | 1x10-6/℃ | 8 | ||

| Electrical Properties | Dielectric Strength(1mhz) | kv/mm | 15 | |

| Dielectric Constant(1MHZ) | 25℃ | 9.9 | ||

| Volume Resistivity | ohm-cm(20℃) | >10^14 | ||

| ohm-cm(300℃) | 10^13 | |||

| ohm-cm(500℃) | 10^10 | |||

Our Company

Wuxi Special Ceramic Electrical mainly produces alumina, Silicon nitride, Zirconia, Steatite, Boron nitride, Cordierite,mullite products, widely used in metal welding, electronic conductor, mechanics, assembling, insulation, chemicals, instrument, textile, nuclear industry, aerial field.We accept trial produce according to the drawing or sample.It usually takes 15 days to finish trial product.Mass produce usually takes 30 days.Goods' package is carton or PLT.It can be negotiable with each other.

We mainly sell goods to toshiba lighting group in Japan and Europe.Our aim is to deliver goods with high quality at quick delivery date.